Iced Up Solar Panels

A quick comment about ice on PV (and likely other) solar panels.

My solar panels are quite flat - about 15 degrees up from the horizontal. Its all related to the wind loading on the roof / ballasted mounting trays.

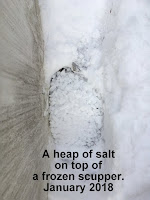

They do get iced over periodically - freezing rain, melting snow, ice storms - a variety of meteorological challenges.

I have found that if you can keep the snow off them with regular / frequent (daily) sweeping, then the heat generated by sun on the panels will clear the ice (mm) in about a day. Unless its really thick (cm), when it might take a week. PV solar panels run warm because they are a near-black colour, and this clears the ice naturally.

Please note that it won't clear deep (cm) snow because snow prevents them from warming up. The whiteness of the snow reflects the sun, especially when compared to the energy absorbed by the black solar crystals, even through clear ice.

So far I have only tackled the clearing ice from the panels only once - following a major ice storm that accumulated well over an inch of ice on all the panels. After a few days of melting, I was able to gently lever the remaining plates of ice from most of the panels, but was constantly petrified of breaking them. Not for the faint of heart. Not sure that I would do it again, mainly based on the risk of panel breakage relative to the speed at which snow-free panels can clear themselves.

It is my experience that I sweep the panels free from snow and heavy frost about 15 times per winter season. Usually before 9 AM.

Here is today's power chart. The panels were swept between 10 and 10:15 this morning.

It is the difference between Wh per day and kWh per day, and the latter pays the bills! I need 6 kWh each day to pay for the loan. I should get it today, but would have achieved it more easily if I had swept the system at 8:30.

If I was doing it over - another PV system from scratch - I would look at more steeply angled panels right up to the 43 degrees that are theoretically optimal here in Toronto. That angle might help with shedding of snow (reduce the need for sweeping) and the draining of rain water. However, I would also have many fewer panels because of the shading. If you need 60 or 80 degrees of slope to shed all snow, then you will need a large or steeply sloping roof if you want an numerous array.

Hmmm. Might have to do some more modelling of the performance vs the panel geometry.

So the bottom line is that to add to your bottom line you need to keep your PV solar panels clear and snow free if you want them to function properly in the winter. The ice will usually look after itself.

Always be careful about roof top safety when sweeping. Falling off the roof is usually quite detrimental to one's health and well-being.